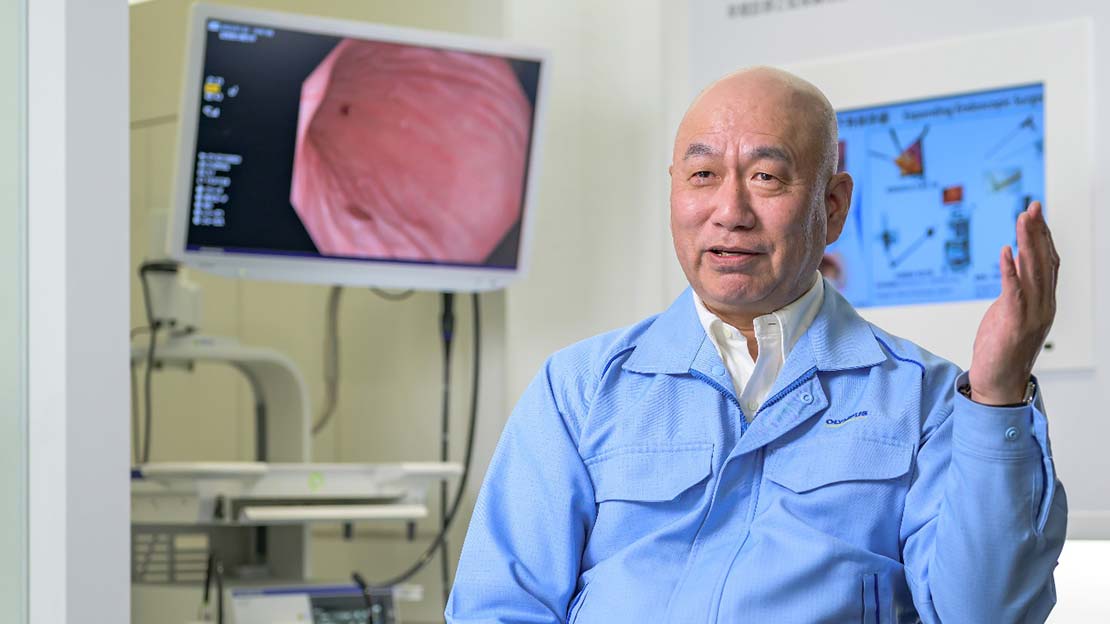

After graduating from a local technical high school, Shoji joined Aizu Olympus and has been devoted to the manufacturing of endoscopes for 40 years. He has continued to focus on monozukuri. Most of the employees at Aizu Olympus, including Shoji, are from the local area of Aizu. The character of the people of Aizu is that of traditional artisans who are tenacious and patient. This kind of character is perfectly suited for the precision manufacturing of endoscopes.

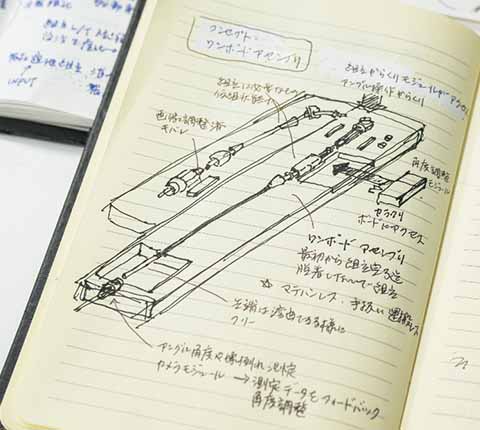

“The characteristics of endoscope manufacturing is the fine and specialized manufacturing process. For this reason, there are many things that cannot be done with commercially available tools and equipment, so we have to prepare these ourselves. In some cases, we need blades to cut parts with an internal diameter of just 1mm, so we need to achieve micron-level precision.” (Shoji)

Aizu Olympus is the mother factory for Olympus' endoscope manufacturing. It has approximately 70% share of the global market for gastrointestinal endoscopes. It could be said that almost all the endoscopes used in hospitals around the world are manufactured by Aizu Olympus.

The endoscope product line exceeds 300. Its feature is high-mix minimal-volume production. This is because they have listened carefully to the voices of healthcare professionals and carefully shaped their detailed requests into reality. The meticulous and tenacious nature of the people of Aizu is clear.