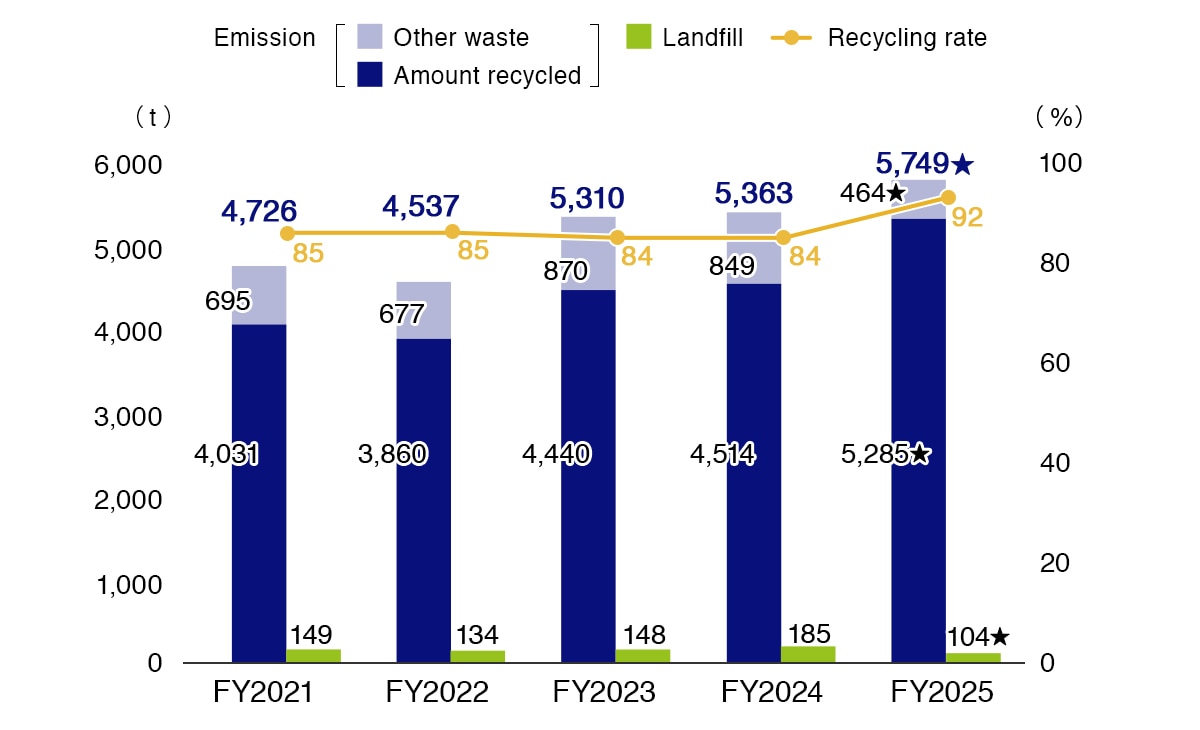

Olympus Vietnam Co., Ltd. (OVNC) previously used a treatment method for discharge water containing chemicals from the sterilization process (sterilized water) involving the landfilling of the residue following incineration of wastewater. However, the company has now switched from this treatment method to chemical treatment, introducing technology to separate such discharge water into purified water and chemicals. This has enabled the recycling of separated chemicals and thereby facilitated an improved recycling rate.

Initiatives for Natural Capital and Waste

- Basic Approach

- Effective use of water resources

- Proper management and reduction of waste

- Chemical substance management

Basic Approach

In recent years, it has been pointed out that the loss of biodiversity and the degradation of natural capital could have grave impacts on the global environment, society, and economic activities. Against this backdrop, it has become increasingly important to achieve an accurate understanding of the impacts of corporate activities on natural capital and to manage and disclose this information in a sustainable manner.

The Olympus Group recognizes that biodiversity is an indispensable element in the soundness of the global environment as well as in the richness of our lives and has remained continually engaged in initiatives to conserve biodiversity. These include management of water use and wastewater at each site as well as the maintenance of green spaces and community cleanup, forest conservation, and tree-planting activities. In addition, the Group regards the reduction and appropriate management of waste as important initiatives, and thus promotes resource recycling and appropriate processing of hazardous substances while striving to reduce impacts on the natural environment.

Based on such developments of recent years, it is becoming increasingly important to identify risks and opportunities regarding which business activities depend on or have an impact on natural capital and to manage the key risks and opportunities in accordance with international initiatives such as the TNFD*1 and SBTs for Nature.*2 The Olympus Group has adopted the LEAP approach*3 recommended by the TNFD for the achievement of a high degree of balance and compatibility between the conservation of natural capital and sustainable business activities, and begun analyzing and evaluating risks and opportunities related to natural capital (the land, sea, freshwater, and air).

*1 Task Force on Nature-related Financial Disclosures. An international organization that develops frameworks for appropriately assessing and disclosing risks and opportunities relating to natural capital and biodiversity in corporate activities. (Source: Ministry of the Environment)

*2 Science Based Targets for Nature. Measurable, actionable, and time-bound objectives relating to the interconnected systems of water, biodiversity, land, and oceans in value chains based on the best available science that allow actors to align with Earth’s limits and societal sustainability goals. (Source: Ministry of the Environment)

*3 An integrated approach which comprises the four steps of “Locate,” “Evaluate,” “Assess,” and “Prepare,” to evaluate nature-related issues such as interfaces with, dependencies on, and impacts on nature, as well as nature-related risks and opportunities.

Related sites

- Information disclosure based on the Taskforce on Nature-related Financial Disclosures (TNFD)

- Guidelines for the Use and Procurement of Paper

- Introduction of Olympus Corporate Citizenship Activities (until FY2021)

Effective use of water resources

Water Use/Wastewater Results

Changes in water consumption

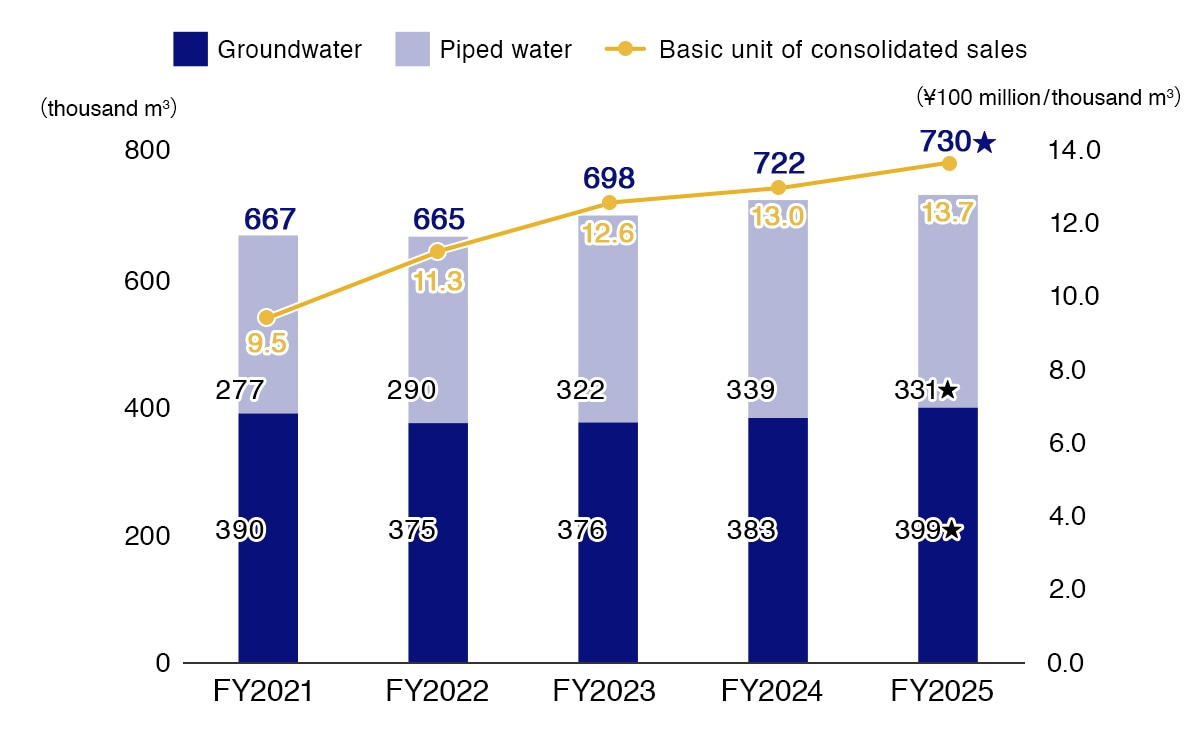

The Olympus Group uses water mainly in production processes, such as for cleaning components and cooling, as well as in its employee cafeterias. Each site implements thorough management of wastewater quality by establishing more stringent standards than the legal requirements in each region. At the same time, we promote initiatives to reduce water usage and discharge volumes, by setting targets for water use efficiency and implementing measures such as those to improve water usage processes, prevent leakages during equipment inspections, and secondary use of water. Through these initiatives we have achieved an 8% improvement in water use efficiency in FY2025 compared to FY2024.

As a major initiative, Aizu Olympus in Japan is furthering efforts to reduce water use by improving manufacturing processes, including cutting down on cleaning processes through the use of solderless technology and optimizing flow volumes for water used for cleaning. Global Headquarters have adopted a rainwater storage and reuse system, to optimize water usage and promote resource recycling and reduced water consumption by utilizing this water for the irrigation of garden spaces. In addition, we have implemented environmental e-learning as part of awareness-raising efforts aimed at all employees, to convey the importance of conserving water resources and inform and educate on specific water-saving practices for water usage both in domestic settings and in manufacturing and thereby encourage individual awareness and actions. Furthermore, we are actively engaged in initiatives in collaboration with local communities for the conservation of regional water resources through activities such as river cleanup efforts.

In FY2026, we will aim to further improve water use efficiency by promoting initiatives to conserve water through reuse, in addition to improving our facilities and manufacturing processes.

Topics: Establishment of an Advanced Water Treatment Plant

Olympus Medical Products Portugal, Unipessoal LDA has introduced equipment for the advanced treatment of wastewater from manufacturing processes, and is promoting initiatives for the reuse of the treated water for landscaping on their premises.

URL:https://www.olympus.co.uk/company/en/about-olympus/social-responsibility/environment/ ![]()

Related sites

Water consumption / Waste water (Environmental Data)(Excel: 57KB) ![]()

Proper management and reduction of waste

Waste Emissions Results

Waste emissions and landfill volumes

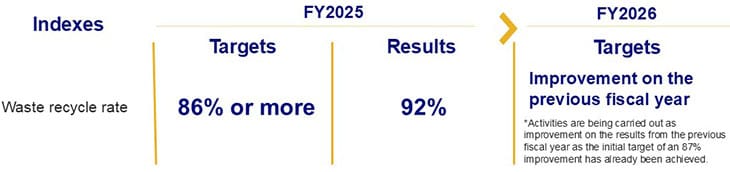

The Olympus Group undertakes initiatives to reduce processing loss through improvements to manufacturing processes as well as those for the efficient use of resources, including mitigating the amount of waste generated thorough separation of discharged waste, extract valuable materials, and promote recycling. In FY2025, the waste recycling rate was 92%, an improvement on the previous fiscal year.

As a major initiative, Aizu Olympus in Japan has promoted the recovery of value materials from waste cooking oils, recycling of used work clothes, and reducing material waste through improvements to product manufacturing processes. Olympus Surgical Technologies America Inc. in the United States, has promoted the recycling of personal protective equipment (PPE) waste used in medical settings at its Bartlett site. The company has also joined the Tennessee Recycling Coalition,* with the aim of exploring new recycling methods and developing and expanding the scope of the reuse and recycling market and is currently engaged in other considerations toward the reduction of waste volumes. At its Westborough site, the company has implemented recycling of machine oils and metals. Olympus KeyMed has switched from landfill disposal to recycling by establishing dedicated collection boxes for food waste to promote sorting.

In addition, The Olympus Group outsources the appropriate processing and disposal of those wastes generated that are difficult to reuse in-house to specialized waste processing and disposal contractors.

In Japan, we implement on-site inspections of industrial waste processing and disposal contractors to coincide with the conclusion of new contracts or at a frequency of once every three years, to safeguard against illegal or improper disposal by such contractors, and thereby confirm that appropriate outsourced waste processing and disposal is being carried out.

In response to hazardous waste, we are promoting measures such as a changeover to the use of less hazardous materials and to recycling. Despite an increase in the volume of our activities in FY2025, we succeeded in keeping the amount of hazardous waste generated at an approximately equivalent level to that generated in FY2024.

In FY2026, we will continue to promote recycling initiatives by diversifying resource recovery methods and enhancing measures to reduce waste generation.

* Tennessee Recycling Coalition: A non-profit organization dedicated to promoting recycling and resource management practices in Tennessee, U.S.

Topics: Recycling Sterilized Water

Topics: Promotion of Waste Separation and Composting

Olympus Surgical Technologies America Inc. recovers resources from approximately 15 tons of food waste, which was previously incinerated, from its cafeteria each year, by separating and composting this waste.

Related sites

Waste emissions/Landfill (Environmental Data)(Excel: 57KB) ![]()

Hazardous waste discharged (Environmental Data)(Excel: 57KB) ![]()

Chemical substance management

Proper Management of Chemical Substances

The Olympus Group strictly complies with laws and regulations relating to chemical substances in Japan and overseas. We restrict the use of hazardous substances in our products and manufacturing processes to provide safe and reliable products based on legislation such as the REACH Regulation and the RoHS Directive. We are also undertaking initiatives to reduce the use of hazardous chemicals in our products and manufacturing processes with the aim of reducing the environmental impact of chemical substances. We are contributing to the realization of a sustainable society by promoting the introduction of alternative materials and technologies.

We consider the safety and health of employees who handle chemical substances at manufacturing and research and development sites as its highest priority, and therefore promote the creation of safe workplaces by regularly holding safety education and training, providing appropriate protective equipment, and improving working environments. We furthermore conduct emergency drills premised on minimizing damage in the event of a chemical leak or spill while maintaining appropriate management conditions for chemical substances by means of inspection and patrol activities.

In Japan, we undertake initiatives for appropriate management and reduction of discharges of substances subject to the PRTR Law, as well as for volatile organic compounds (VOCs), and other chemical substances in order to minimize the impacts from the use of chemical substances on people and the environment. We conduct environmental impact and chemical substance risk assessments prior to the introduction of any new chemical substances and undertake measures to substitute these with safer chemical substances or those to reduce risks in workplaces at which chemical substances are used.

Topics: Promotion of Advanced Companywide Chemical Substance Management

(Enhancement of systems through the introduction of an integrated system)

In Japan, chemical substances have to date been managed using different information management platforms at each site. However, we are now improving the accuracy and efficiency of information management through the introduction of a Company-wide, integrated IT system. This initiative is furthering the establishment of a more reliable compliance system for chemical substances.

Topics: Emergency Drills for Chemical Leaks

We conduct emergency response drills premised on hazardous chemical leaks at manufacturing and development sites of the Olympus Group. Such drills are used to facilitate knowledge acquisition on emergency response procedures and regularly confirm the status of emergency response equipment and protective gear to thereby ensure that we are prepared in the event of any emergency.

Emissions and Movements of PRTR Class 1-Designated Chemical Substances

| FY2021 | FY2022 | FY2023 | FY2024 | FY2025 | |

|---|---|---|---|---|---|

| Emissions and Movements of PRTR Class 1-Designated Chemical Substances | 13 | 12 | 10 | 10 | 12 |

* Scope: Manufacturing and development sites in Japan

Volatile Organic Compound (VOC) Emissions

| FY2021 | FY2022 | FY2023 | FY2024 | FY2025 | |

|---|---|---|---|---|---|

| Volatile Organic Compound (V OC) Emissions (t) | 39 | 41 | 45 | 47 | 36 |

* Scope: Manufacturing and development sites in Japan