Product Stewardship

- Basic Approach

- Environmental considerations for products and packaging

- Life Cycle Assessments of Existing Products

- Approaches to plastics

Basic Approach

Product stewardship refers to initiatives to ensure the quality and safety of products and packaging at all stages of their life cycle (development, raw material procurement, manufacturing, transport, use, repair, disposal, and recycling), and to minimize the risk of impacts on people and the environment.

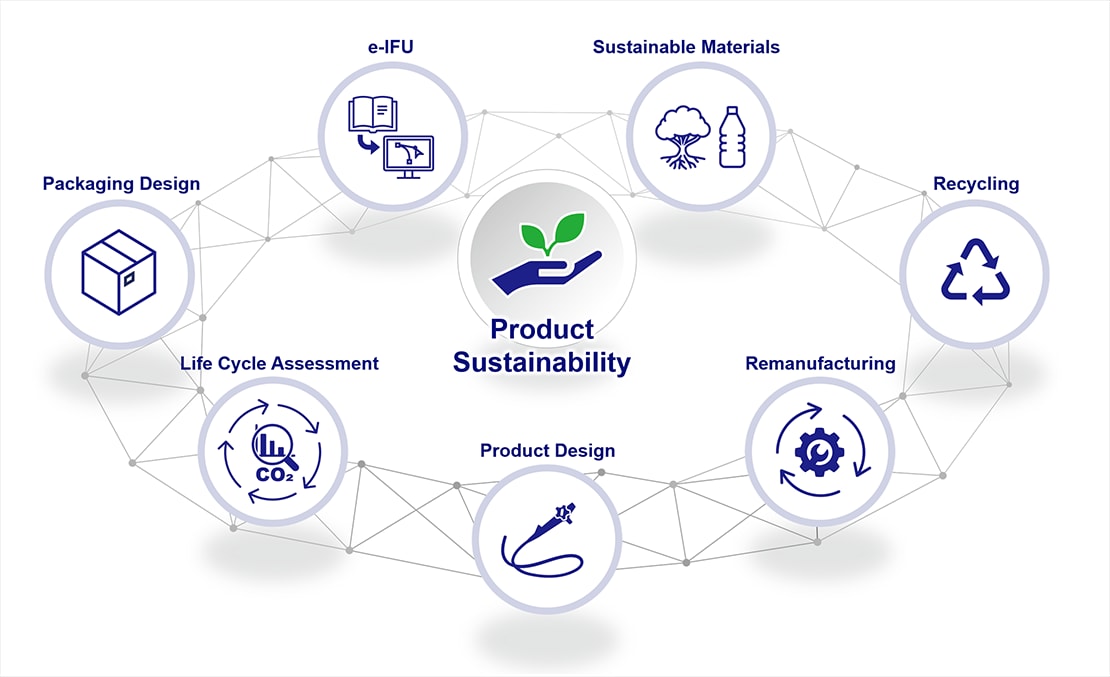

The Olympus Group pursues the environmentally conscious design (eco-design) of products and packaging materials in product development for patient- and environmentally-friendly sustainable healthcare. In FY2025, Olympus newly established the Eco-friendly Product and Packaging Design Guidelines. We recognize that expediting our initiatives to improve “Product Sustainability” is one of the materiality topics in maintaining our leadership in the global MedTech industry. For this reason, we are committed to “achieving a circular economy through product stewardship,” instituting a dedicated promotional unit within our development functions, and are promoting initiatives in the following seven priority areas as environment, society, and governance (ESG) initiatives in our company strategy announced in May 2023.

Environmental considerations for products and packaging

In FY2025, we undertook the following initiatives, mainly in the areas of “Product Design,” “Packaging Design,” and “e-IFU.”

Product Design

We have established global guidelines titled “Eco-friendly Product and Packaging Design” for the specific implementation of the eco-design of products. These guidelines include a list of eco-design items that should be considered in the design of sustainable products. We have conducted e-learning for all relevant personnel worldwide to ensure that these guidelines are appropriately implemented.

Packaging Design

For the eco-design of packaging, we are currently undertaking considerations for the simplification of external labelling and a review of packaging materials.

These can be expected to reduce the amount of ink used in external labelling and to improve recyclability after use. For the review of packaging materials, we are considering the use of recycled materials with low environmental impacts while remaining conscious of the safe transport of products, endeavoring to reduce usage amounts to promote the effective use of resources.

Commitment to Sustainable Materials

Olympus has begun a collaboration with DuPont to use their product Tyvek® with Renewable Attribution, which has renewable attributes, in the sterilization packs and other components of our single-use products. Tyvek® with Renewable Attribution is a mass-balanced product that uses renewable raw materials to replace fossil fuel-based materials in the polymer supply chain, ensuring the same durability, safety, and performance as conventional products. The supply of renewable raw materials used in Tyvek® with Renewable Attribution is carefully tracked through the ISCC certification process by the mass balance method, which certifies that renewable raw materials were used. By adopting Tyvek® with Renewable Attribution, Olympus is taking an important step toward minimizing its fossil resource use and carbon footprint.

Management of Chemical Substances Contained in Products: PFAS

Olympus is conducting surveys on the usage status of per-and polyfluoroalkyl substances (PFAS) and is considering countermeasures. We do not currently use any PFAS subject to regulation in our products.

e-IFU

We are undertaking considerations on the digitization of instructions manuals to reduce the amounts of paper used therein, in compliance with laws and regulations in each locality. We thereby aim to achieve savings on paper resources and to reduce CO2 emissions during transportation, while prioritizing product safety and improving usability.

Life Cycle Assessments of Existing Products (Environmental Consciousness Assessments; Carbon Footprints [CFPs])

The Olympus Group performs evaluations of environmental impacts at the product development stage, for each stage of a product's life cycle from procurement through manufacture, transport, use and final disposal, to identify considerations in their environmental consciousness for each product category and promote environmentally conscious measures.

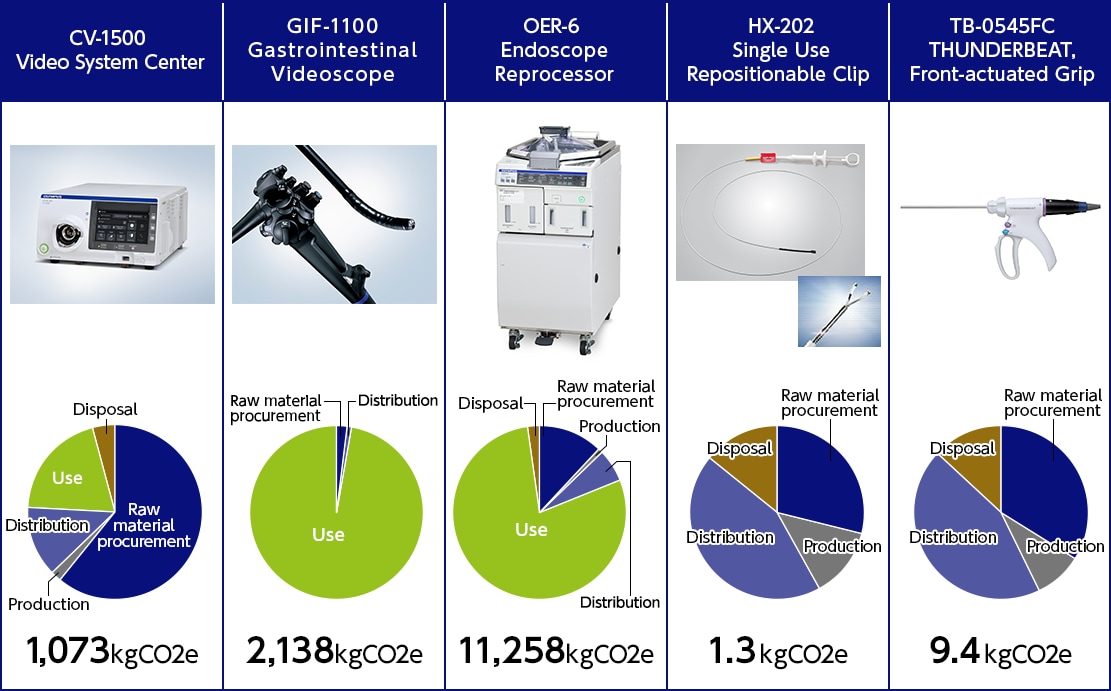

In FY2024, we conducted case studies for five major product models at Olympus to quantitatively assess their greenhouse gas (GHG) emissions over the entire lifecycle of these products (carbon footprint: CFP). This provided us with many insights toward more effectively designing for environmental consciousness going forward, with the stages at which impacts occurred and the magnitudes of these impacts differing according to the product category. In FY2026, we are planning to expand the scope of products subject to GHG emissions assessments.

*We calculate the CFP in question in accordance with the approach set out in the ISO. However, results will differ depending on the scope of calculations and the basic units used. Accordingly, a comparison of the numerical values with equivalent products from other companies is not possible.

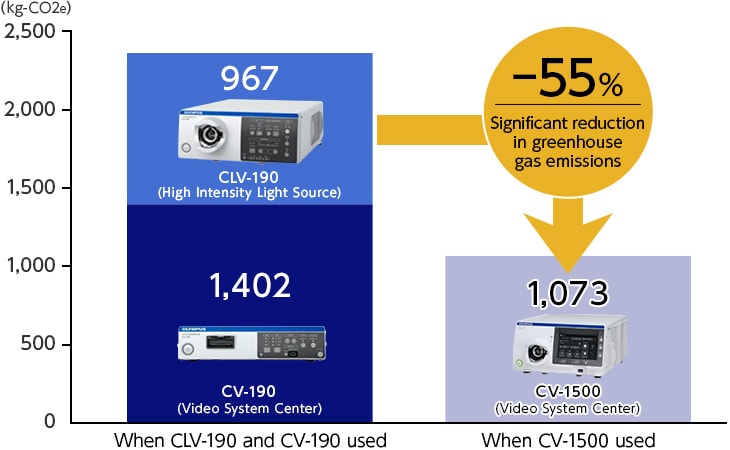

In addition, the EVIS X1 CV-1500 (Video System Center), which represents the latest model, combines the functions of the EVIS EXERA III CV-190 (Video System Center) and CLV-190 (High Intensity Light Source) into a single unit. Calculations indicate that, this combination into a single unity contributes to a significant reduction in greenhouse gas emissions when compared to using the Video System Center and High Intensity Light Source separately.

In the future, we will expand the scope of products subject to CFP calculations and home in on the key factors in reducing greenhouse gas emissions. At the same time, we are committed to continuously promoting initiatives involving, for example, incorporation of these considerations into the design and development process.

Approaches to plastics

Participation in the Healthcare Plastic Recycling Council (HPRC)

In April 2024, the Olympus Group joined the Healthcare Plastic Recycling Council (HPRC) in the United States. By joining the HPRC, Olympus will forge partnerships with other member organizations in the value chain, and is also anticipating the opportunity to gain technical knowledge of the industry while engaging with clients. This will include, for example, gaining a deeper understanding of the potential, and technical challenges, in the recycling of healthcare plastics* and producing models on the potential to recycle products and packaging in which plastics are used on a global scale. The recycling of healthcare plastics is consistent with our ESG objectives of reducing Scope 1, 2, and 3 CO2 emissions and improving the recyclability of medical devices.

*Healthcare plastics refers to plastic materials used in the healthcare sector. Healthcare plastics are used in the manufacture of a wide range of medical devices and instruments, as well as in pharmaceuticals packaging and medical equipment.