Initiatives for Climate Change

Basic Approach

Since establishing the Olympus Group Environmental Charter (currently the Environmental Health and Safety Policy) in 1992, the Olympus Group has committed itself to the reduction of its environment impact throughout product lifecycles, including promoting energy conservation activities and the introduction of renewable energy at its sites, the development of environmentally-conscious products, and the implementation of green procurement in collaboration with suppliers. In recent years, the intensification of natural disasters and depletion of resources caused by climate change and the issue with marine plastics has become increasingly serious, posing the dual risk of threatening the entire global environment and directly impacting the sustainability of corporations. Recognizing these challenges as an opportunity for growth as well as operating risk, under the banner of contributing to the achievement of “Carbon Neutral Society and Circular Economy” as a focus area under its ESG strategy, we are promoting initiatives aimed at realizing such a society and economy.

Moreover, in our environmental initiatives, we support the recommendations of the TCFD (Task Force on Climate-Related Financial Disclosures), and conduct disclosures concerning our governance system, the identification of risks and opportunities, our risk management system, and associated targets.

Related sites

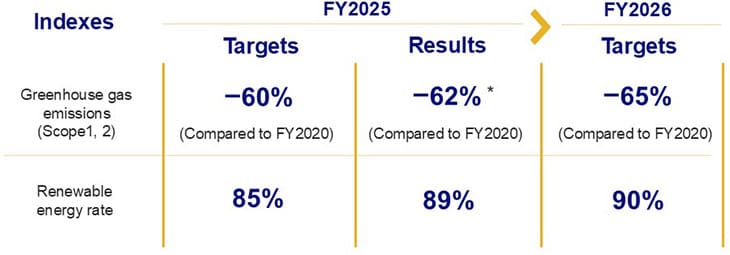

Environmental Goals and Progress

Internal (Scope 1, 2) Results

* Comes to -70% (compared to FY2020) when emissions reduced through offsetting using carbon offset gas are included.

<Changes in Scope 1 and 2 Emissions>

The Olympus Group set a target of achieving carbon neutrality for greenhouse gas emissions from its site operations (Scope 1 and 2) by FY2031. With a view to this target, we are continuing to engage in the ongoing implementation of manufacturing improvement activities and the introduction of energy-saving equipment as well as routine energy conservation activities in the form of shutting off lights and properly controlling the temperature of air conditioning. Furthermore, we are bolstering our organizational initiatives, including appointing energy-saving experts and establishing a system to promote energy conservation at sites where energy consumption is high. In addition, by also promoting the active introduction of renewable energy and the utilization of environmentally conscious cars in its business activities, we are endeavoring to further reduce greenhouse gas emissions.

In FY2025, continual improvements in manufacturing, energy-saving measures, the updating of company-owned cars to environmentally conscious cars and the use of renewable energy were implemented at its sites around the world. As a result of these initiatives, greenhouse gas emissions in FY2025 were reduced by 62% compared to FY2020 (55% reduction in FY2024), the renewable energy use rate vis-á-vis the total electric power consumption increased substantially to 89% (78% in FY2024).

For our main initiatives in this regard, in the Americas, we shifted the power used at the Westborough site of Olympus Surgical Technologies America (Gyrus ACMI, Inc.) and the Center Valley and Breinigsville sites of Olympus Corporation of the Americas to power derived from 100% renewable energy. At sites in Japan, while we had already been making the transition to 100% renewable energy through power retail supply contracts, starting in April 2025, we commenced the supply of renewable energy through an offsite corporate PPA service at our Global Headquarters, Aomori Olympus, Aizu Olympus, and Shirakawa Olympus with a view to expanding renewable energy across society at large.

Moreover, we are also moving forward with initiatives to make the gas used at our various sites carbon neutral. We have completed the switchover of all quantities of gas used at those sites, including city gas and LPG, to carbon offset gas. We commenced the introduction of carbon offset gas at our Global Headquarters in April 2021 and at the Shirakawa site in October 2023. Furthermore, we completed the introduction of carbon offset gas at Aizu Olympus and Olympus Medical Systems (Hinode Plant) as well as at Olympus UK & Ireland and Algram Group Ltd. in Europe this fiscal year (which contributed to approx. 6,400t in CO2 reductions through switching to carbon offset gas), and did the same at Aomori Olympus in April 2025.

In FY2025 as well, we continue to promote manufacturing process improvements and energy conservation measures while simultaneously accelerating initiatives aimed at reducing greenhouse gas emissions, including gradually switching all power consumed at Olympus sites to renewable energy.

Topics: Environmental consciousness at buildings (Nagano site)

At our Nagano site in Japan, we took the opportunity posed by the construction of a new building to introduce environmentally-conscious equipment. For example, in addition to installing a solar power generation system on the roof, we changed the fuel used in air conditioning apparatus from gas to electricity. We also make daily energy reductions through meticulous management conducted with power monitoring and control air conditioning apparatus using multiple sensors in order to promote energy-saving in clean rooms. Alongside these energy conservation measures, for power consumed at the Nagano site, we also continue to enter contracts to receive the supply of power derived from 100% renewable energy.

Topics: Fully meeting renewable energy targets (Vietnam site)

Having installed solar power generation panels on the roof of its plant in July 2024, Olympus Vietnam Co., Ltd. (OVNC) commenced the introduction of renewable energy through an onsite corporate PPA service.* In addition to this, the company made use of I-REC, an international renewable energy certificate, to shift the power it consumes at the Vietnam site to 100% renewable energy.

In doing so, OVNC is planning to contributes to roughly 4,800t in CO2 emission reductions, amounting to approx. 10% of total emissions across the Olympus Group.

* For this particular project, a Joint Crediting Mechanism (JCM) between Japan and Vietnam is utilized.

Topics: Commenced introduction of offsite corporate PPA service through main manufacturing subsidiaries in Japan

In April 2025, Aomori Olympus, Aizu Olympus, and Shirakawa Olympus, which constitute the Olympus Group’s main manufacturing subsidiaries in Japan, introduced an offsite corporate PPA service to procure power derived from renewable energy from offsite sources. While we have already made the transition to 100% renewable energy through power retail supply contracts for power consumed at our main manufacturing sites in Japan, we also introduced renewable energy through this service at our main manufacturing sites in the Tohoku region (Aomori, Aizu, and Shirakawa) in order to expand renewable energy across society as a whole.

News release (Only in Japanese) ![]()

Green Energy Certificates

Olympus Europa SE & Co. KG (Germany)

KeyMed (Medical & Industrial Equipment) Ltd. (UK)

Algram Group Ltd. (UK)

Olympus Medical Products Portugal, Unipessoal LDA (Portugal)

Olympus Surgical Technologies America: Redmond (Gyrus ACMI, Inc.) (USA)

Olympus Vietnam Co., Ltd. (Vietnam)

Logo for the Carbon Neutral LNG

Shirakawa Olympus

Aizu Olympus

KeyMed (Medical & Industrial Equipment) Ltd. (英国)

Algram Group Ltd.(英国)

External (Scope 3) Results

The Olympus Group ascertains and calculates greenhouse gas emissions throughout the entire supply chain for each category and is taking action to reduce greenhouse gas emissions through green procurement, improvement of logistical efficiency, development of environmentally conscious products, and other measures. In addition, we encourage the suppliers with which we do business to set voluntary targets for the reduction of greenhouse gas emissions and to undertake initiatives for continuous reductions of emissions. We also check the status of initiatives to ascertain, set targets for, and reduce greenhouse gas emissions of these suppliers through a web-based company survey on ESG.

These efforts have been recognized, and we have been selected as a “CDP 2024 Supplier Engagement Leader,” the highest rating in the “Supplier Engagement Rating (SER)” conducted by CDP*, an international non-profit organization.

As shown in the graph, Scope 3 greenhouse gas emissions account for 90% or more of all Olympus Group supply chain greenhouse gas emissions (Scope 1, 2, and 3). Among Scope 3 emissions, the percentages of upstream greenhouse emissions from purchased goods and services (category 1), capital goods (category 2), and upstream transportation and distribution (category 4) are extremely high.

As such, with a view to achieving the long-term target of net-zero greenhouse gas emissions by 2040, we have set forth “80% of our suppliers achieving science-based greenhouse gas reduction targets (targets whose basis is emissions from purchased goods and services, capital goods, and upstream transportation and distribution) by FY2028” as a short-term target for Scope 3 alone, and are commencing initiatives geared towards reductions of greenhouse gases, in cooperation with our suppliers.

In FY2025, we collaborated with suppliers to bolster initiatives aimed at achieving carbon neutrality with respect to “purchased goods and services,” which account for a large percentage of the Group’s Scope 3 emissions. Specifically, to help our main suppliers ascertain their greenhouse gas emissions and set reduction targets, in addition to holding briefings, we individually handled corporations that requested separate consultations, and endeavored to promote understanding through careful explanations and the sharing of information. As a result of such initiatives, as of 2025, suppliers that accounted for roughly 30% of Scope 3 emissions obtained Science Based Targets (SBTs) certification, and started taking action aimed at their adopted science-based greenhouse gas reduction targets. Going forward, as we further deepen our partnerships with suppliers, we will continue to promote carbon neutrality across the entirety of our supply chain.

* CDP is an international non-profit organization founded in the United Kingdom in 2000. CDP collects, analyzes and evaluates information on the environmental activities of major companies around the world, and discloses the results of these to institutional investors

Greenhouse Gas Emissions (Scope 3)

★ Indexes certified by external assurance.

Purchased goods and services (category 1)

We held briefings and streamed video aimed at grasping greenhouse gases and reducing greenhouse gas emissions for 188 suppliers (conduced a total of three times: in January and August 2024 and in January 2025). At these briefings, we deepened each supplier’s understanding by explaining to them the importance of reducing greenhouse gases, ways to calculate emissions, and methods of setting Science Based Targets (SBTs). Additionally, for our 35 main suppliers in Japan, we held individual briefings where we fielded their questions and gave them practical advice in accordance with the situation at each corporation.

Furthermore, for all our suppliers, we are working to ascertain the status of actions and improvements by each supplier by surveying the status of their environmental initiatives, including their grasp of greenhouse gas emissions, target-setting, water resource management, and waste reduction. Through this survey, we have managed to obtain responses from over roughly 60% of those suppliers (on a transaction value basis).

Upstream transportation and distribution (category 4)

We are undertaking initiatives to improve data accuracy by obtaining greenhouse gas emissions data directly from international logistics forwarders. In addition, we are facilitating reductions in greenhouse gas emissions by actively promoting a modal shift from air to sea for major transportation routes, including from the Hong Kong warehouse to Olympus Europa SE & Co. KG (OEKGOE) while shortening transport distances by eliminating shipments via the Hong Kong warehouse and directly shipping items for shipments from Olympus Vietnam Co., Ltd. (OVNC) to Olympus Corporation of the Americas (OCA).