As a measure against hand and finger cutting accidents, which account for a particularly large number of occupational accidents, we are taking ongoing safety measures that include attaching holders to blades and using the appropriate protective gear (gloves, finger sacks, finger tape, etc.).

Occupational Safety and Health

- Basic Approach and Policy

- Global Safety and Health Organization

- Occurrence of Occupational Injuries

- Employee Training and Education

- Safety for Our Partners

- Regional Activities

Basic Approach and Policy

The Olympus Group has positioned the occupational health and safety of people who work at Olympus as one of its highest-priority management challenges. We endeavor to develop a workplace environment that is conducive to working in a safe and healthy manner based on the Olympus Global Code of Conduct and the Environmental Health and Safety Policy.

More specifically, we carry out the formation and maintenance of management systems for health and safety, the ongoing improvement of those systems, risk reduction activities based on risk assessment, training and drills pertaining to health and safety, and workplace patrols in our aim to realize zero work accidents.

Promotion Structure and Initiatives

Global Safety and Health Organization

The CEO serves as the chief officer for EHS (Environment, Health, and Safety). The CHRO (Chief Human Resources Officer), who supervises the human resource and general affairs functions, has responsibility for establishing the health and safety policy and activity goals as well as the achievement of goals, etc. in the capacity of general manager of EHS operations for the entire Group. Under the instructions of the CHRO, the global EHS management division promotes activities in line with the health and safety activity guidelines for each fiscal year as well as monitors the health and safety activity status of each Group company and site and conducts quarterly management reviews as it endeavors to make ongoing improvements to health and safety activities for the Group as a whole.

Additionally, each Group company and site nominates the head of that company or site as its manager of health and safety management, and promotes health and safety activities tailored to the attributes of that company or site in line with annual activity guidelines for the Group overall. In Japan, a “Health and Safety Committee” that involves the participation of both employees and management convenes at each Group company or site to conduct discussions of the achievement of the annual activity plan as well as discussions aimed at associated improvements.

Regarding the multiple sites that have production, repair and other functions, we will go on to pursue ongoing improvements through acquiring external certifications for our health and safety management system, starting with ISO 45001, and through implementing a PDCA cycle.

Occurrence of Occupational Injuries

In FY2025, the Olympus Group engaged in health and safety activities with the goals of achieving zero accidents resulting in death and a lost time injuries frequency rate of 0.58 or less.

As a result, while we maintained both the number of fatalities involving employees and contractors at zero, one serious accident attributable to the abnormal handling of machinery occurred. For this case, in addition to the swift implementation of corrective measures, those measures were laterally deployed across the entirety of global operations to help prevent the reoccurrence of similar accidents. Additionally, the lost time injuries frequency rate was 0.68, an increase over the previous year. However, the health and safety promotor verified the status of the occurrence of the accident at the actual site and with the actual article, and took measures to prevent reoccurrence through the improvement of equipment, a revision of work procedures and guidelines, retraining in safe behavior and so forth.

For the purpose of realizing a safer, healthier workplace, in addition to measures for and the management of tasks that may lead to serious accidents as identified through risk assessments, we will continue training for elevating the level of safe behavior of people who work at Olympus.

| FY2021 | FY2022 | FY2023 | FY2024 | FY2025 | Target of FY2025 | |

|---|---|---|---|---|---|---|

| Number of fatalities*2 | 0 (0) | 0 (0) | 0 (0) | 0 (0) | 0 (0)★ | 0 (0) |

| Number of lost time injuries | 31 | 27 | 31 | 28 | 32★ | |

| Lost time injuries (of one day or more) frequency rate*3(LTIFR) | 0.62 | 0.56 | 0.66 | 0.60 | 0.68★ | 0.58 |

★ Indexes certified by external assurance.

*2 Numbers in brackets indicate contractors

*3 Lost time injury frequency rate: number of lost time injuries per 1,000,000 working hours

Employee Training and Education

The Olympus Group believes that in order to realize a workplace where its employees can go about their work in a healthy and safe manner, it is imperative that all its employees become able to take appropriate action with respect to health and safety. To that end, we regularly administer training to all our employees with policies and basic rules on health and safety, actions to prevent accidents carried out with respect to machines, chemicals, blades, heavy objects, and other sources of danger, and appropriate notification, evacuation and other forms of response in times of emergency as basic knowledge.

Additionally, health and safety management systems, risk assessments, and specialized and special training for specific job categories were also administered for foremen and special workers.

Safety for Our Partners

Similar to that for our employees, we conduct safety management for contractors who work together with us onsite (dispatch employees, work consignees, etc.) as people who work at Olympus. An example of this is how in the Japan region, we ask contractors to undergo training on health and safety upon onsite acceptance, and how in the Americas region, we conduct initiatives such as handing out leaflets on health and safety to visitors when they enter the site.

Furthermore, in the Olympic Global Third Party Code, we ask our suppliers to comply with applicable laws and regulations related to health and safety in order to provide a safe workplace. Additionally, we monitor the status of those initiatives through ESG assessments and request improvements as necessary.

Regional Activities

Activities in Japan

Opinion exchange sessions on chemical substances

In our aim to realize more effective and more efficient chemical substance management in the entire Group, every other month, we held opinion exchange sessions where knowhow on and experience in chemical substance management in the possession of each site was shared. Various themes that included management platforms for chemical substance information and specialized training on the handling of chemical substances were handled, with activities aimed at the successful sharing of the management platform and training tools and other topics raised in the course of the opinion exchange sessions currently being promoted.

Safety measures based on risk assessments

To prevent serious accidents, each manufacturing site regularly performs risk assessments. For equipment and tasks identified as high risk, action plans for safety measures are devised and the status of those measures are followed up on through the Health and Safety Committee and other bodies. To give an example, measures were carried out for new risks arising from the introduction of new equipment and changes to processes and other areas, such as the change of blades used in the manufacturing process from single-edge razor blades to design knives and the change of twisting work using the wrist to work using jigs.

Activities in Americas

Safety measures for sharp tools

(Olympus Surgical Technologies America)

To reduce cut wound accidents caused by sharp tools, which top the list of work-related accidents, the supervisor at each workplace orders inspections of blades prior to work and the reconfirmation of the position of hands and fingers upon using blades. Additionally, we poste repeated calls for attention upon using cutter knives and blades on onsite signage.

Measures based on ergonomics

(Olympus Surgical Technologies America)

To reduce the occurrence of tendonitis, back pain, and stiff neck and shoulders caused by repeatedly performing work in the same posture for a prolonged period of time, we are working on making improvements to work posture through means such as adjusting cargo racks to their proper height and introducing height-adjustable worktables and chairs as well as by mitigating the burden on wrists with improved tool grips. Additionally, we deploy materials that promote understanding of ergonomics and are endeavoring to maintain the health of workers and improve their work efficiency.

Activities in Europe

Safety evaluations upon the introduction of equipment

(KeyMed (Medical & Industrial Equipment) Ltd.)

Having identified instances of introducing new equipment as valuable opportunities to incorporate more effective safety measures than before, we conduct strict evaluations while factoring the point of view of health and safety specialists. To give a concrete example, upon the replacement of forklifts and pallet stackers that have reached their update timing, we introduced new equipment only after verifying that it was fitted with the latest safety equipment, such as seatbelts, operational warning lights, and impact sensors.

Measures to prevent finger cut wounds

(Olympus Surgical Technologies Europe | Olympus Winter & Ibe GmbH)

Measures based on noise exposure assessments

(Olympus Medical Products Portugal, Unipessoal LDA)

To prevent noise-induced hearing loss and other health problems, we carry out “workplace noise exposure assessments” so that employees are not exposed to loud sounds for a prolonged period of tiime. Based on those risk assessments, we take appropraite measures such as wearing soundproofing ccovers and protective gear, revising work times, and taking other appropriate measures. In doing so, we reduce the risk to employees’ health.

Activities in China

Measures for machinery and equipment based on risk assessment

(Olympus Trading (Shanghai) Limited)

To maintain safety in the workplace, we carry out yearly risk assessments. As the risk assessment for FY2025 resulted in automatic label applicators being identified as high risk, we took measures for the applicators such as installing a protective fence to prevent entanglement as well as a gate to prevent entry into the equipment area by non-work-related personnel.

Workplace safety inspection and drills to prepare for times of emergency

(Olympus Trading (Shanghai) Limited)

Having positioned safety inspections as a key activity for maintaining safety in the workplace, we conduct them every quarter. In particular, we performed inspections while prioritizing fire safety and chemical substance management, and made improvements in the form of revising the layout of chemical substance vaults and organized emergency evacuation routes. Additionally, with the view that preparing for accidents should one occur is of equal importance, every year, we conduct evacuation drills that assume a fire has occurred and emergency response drills that assume ethylene oxide gas (EOG) has leaked.

Activities in Asia/Oceania

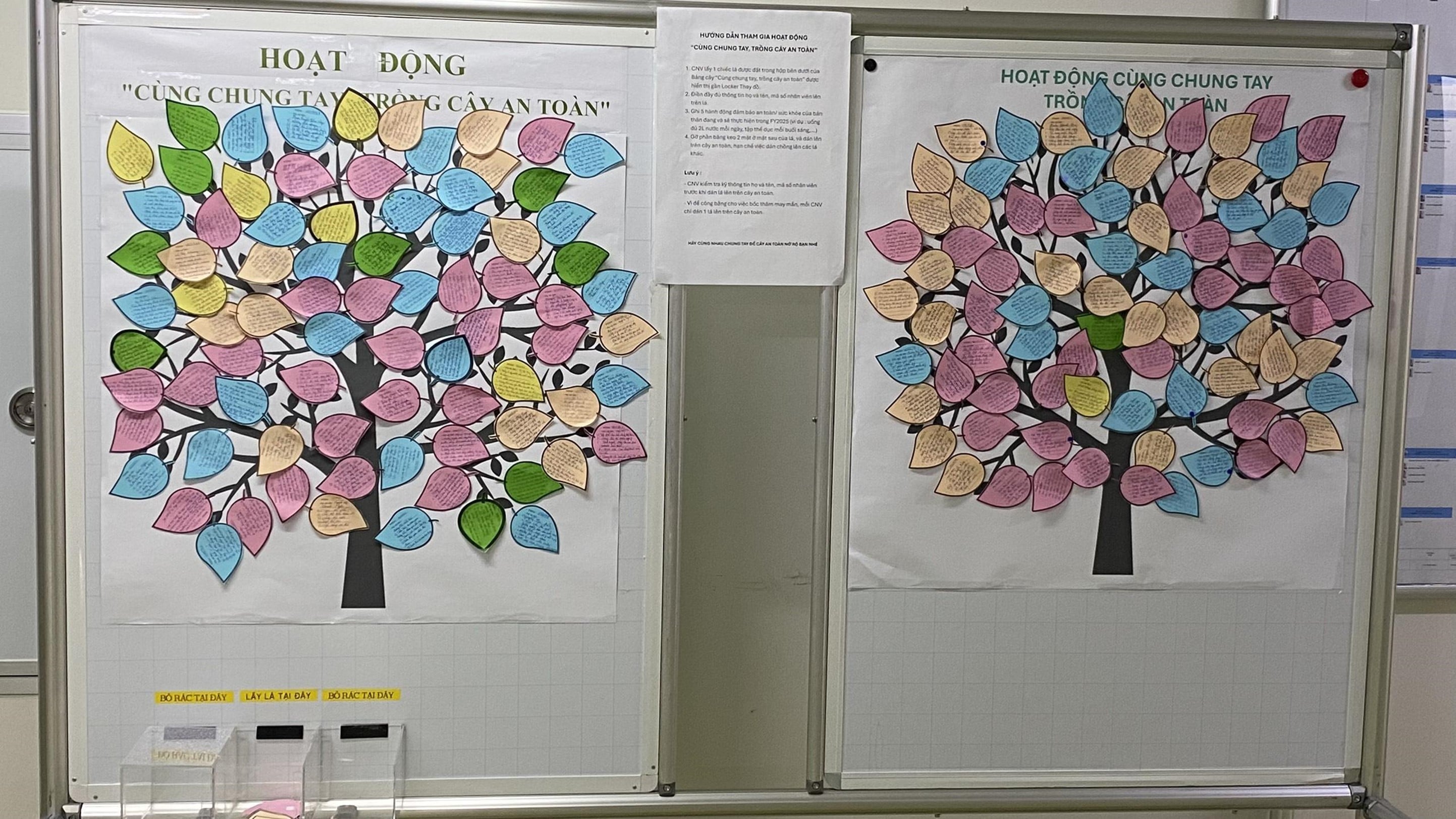

Fostering of safety culture and Improved Safety Awareness Reinforcement Month (Olympus Vietnam Co., Ltd.)

Field survey on health and safety prior to operation of new facility

(Olympus Australia Pty Ltd.)

Ahead of the operation of a newly-built sterilization facility, members of the occupational health and safety division performed a field survey to verify whether it would be possible to further improve the health and safety aspects of the workplace environment. In addition to initiatives addressing equipment aspects such as ergonomic improvements, improvements to locations with fall risk, the storage of hazardous materials, the prevention of their leakage and the ventilation thereof, initiatives addressing operational aspects such as the establishment of first aid and consultation systems and the enhancement of training materials were also applied to improve safety in the workplace environment.

Disaster prevention drills and associated lectures that assume a fire

(Olympus Corporation of Asia Pacific Limited & Olympus Hong Kong and China Limited)

Training and enlightenment on safe driving

(Olympus Korea Co., Ltd.)

Given that traffic accidents can potentially lead to serious consequences, it is essential for all employees to increase their awareness of safe driving and adopt safe driving practices. For that purpose, throughout the year, we distributed messages in accordance with the time of year that covered the likes of the current state of traffic accidents, falling asleep at the wheel, and safe driving during the rainy season to boost awareness of safe driving.