Designed for the Inspection and Quality Management of Car Parts and Other Metal Components Launch of the GX53 Inverted Metallurgical MicroscopeOLYMPUS Stream Image Analysis Software Upgraded to Version 2.3

November 2, 2017

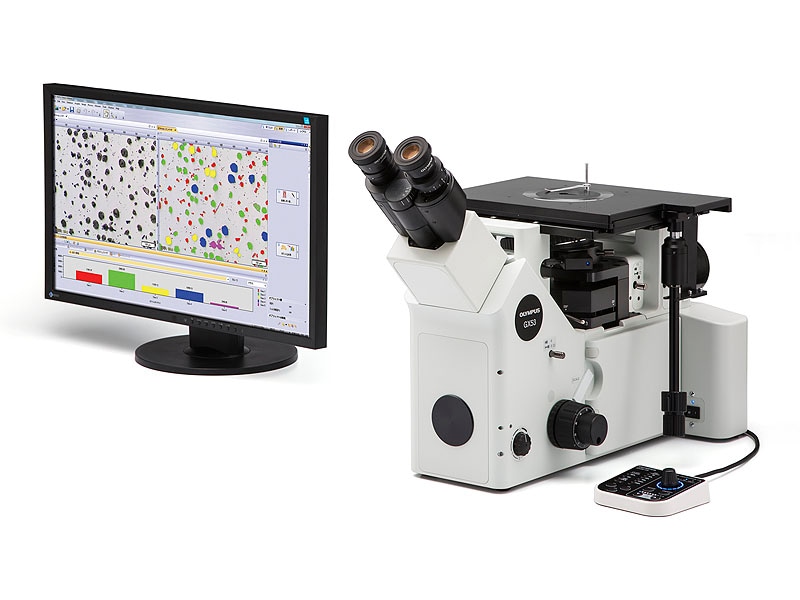

GX53 Inverted Metallurgical Microscope and OLYMPUS Stream v. 2.3 image analysis software

Olympus Corporation (President: Hiroyuki Sasa) today announced the immediate worldwide launch of the GX53 inverted metallurgical microscope, a new product from its Scientific Solutions business for the observation and inspection of metal components. A new version of the OLYMPUS Stream software for analyzing observations has also been released.

Inverted metallurgical microscopes observe samples from underneath, enabling the user to inspect thick or heavy samples without adjusting the orientation of the sample surface. They are suitable for viewing the microstructure of metals used in automotive and other manufactured metal applications or for viewing cross-sections of electronic components on printed circuit boards.

The new GX53 microscope features an LED light source for ultra-long life and low power consumption. With the incorporation of a MIX observation1 unit — a first for the GX series — the GX53 microscope can obtain surface structure images with greater clarity. The upgraded version of OLYMPUS Stream image analysis software, meanwhile, uses image synthesis to provide clear images with minimal halation2, even from highly reflective samples. An available function for saving observation conditions improves user productivity and facilitates inspections by recording settings such as brightness and observation technique.

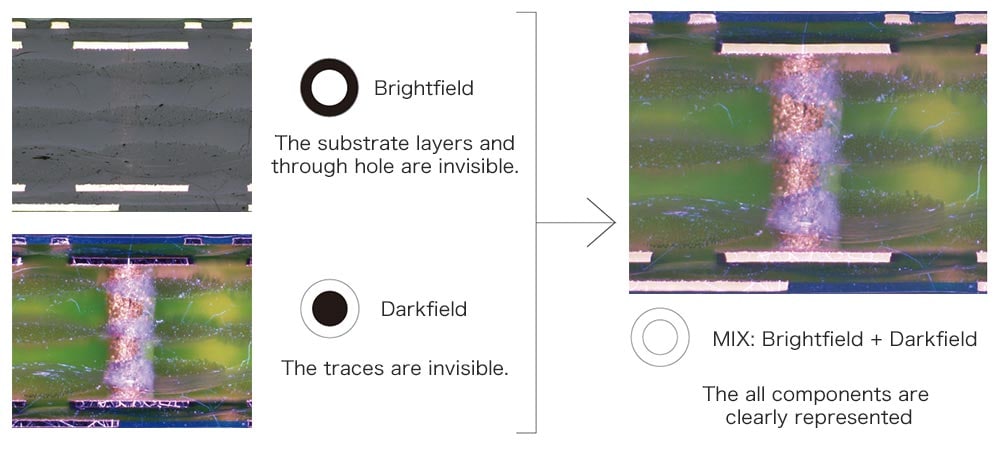

1 An observation technique that combines darkfield observation (an excellent technique for detecting fine structures and defects) with other techniques, such as brightfield observation (suitable for imaging entire samples, including color information) and simple polarized light observation (which highlights metal microstructure and composition characteristics in the form of clear interference colors).

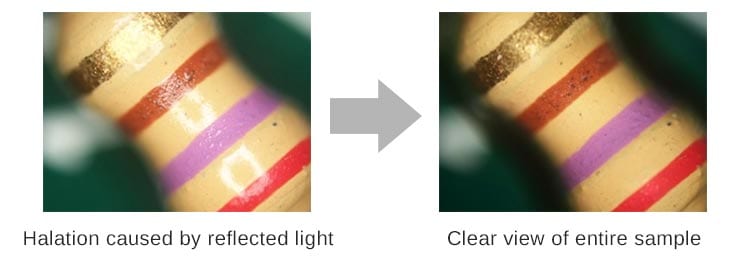

2 The whiteout effect (spreading of light beyond its proper boundaries) caused by reflection when an image is projected.

Launch Overview

| Name | Launch Date |

|---|---|

| GX53 Inverted Metallurgical Microscope | November 2, 2017 |

| OLYMPUS Stream v. 2.3 image analysis software | November 2, 2017 |

Main Features

- New MIX observation function contributes to clear imaging of microstructures and other surface features

- Clear images, even from reflective samples

- Coded hardware saves observation settings for faster inspections and improved productivity

Details of Main Features

1. New MIX observation function contributes to clear imaging of microstructures and other surface features

MIX observation combines darkfield observation (an excellent technique for detecting fine structures and defects) with other techniques, such as brightfield observation (suitable for imaging entire samples, including color information) and simple polarized light observation (which highlights metal microstructure and composition characteristics in the form of clear interference colors). The result is a single combined image that takes advantage of the respective merits of the different techniques used to provide a full view of the sample and its coloring while also enabling visibility of fine cracks or microstructural features.

Cross-section of a printed circuit board

2. Clear images, even from reflective samples

OLYMPUS Stream image analysis software v. 2.3 can combine different darkfield illuminations (partial illumination of the sample from different directions) to provide clear images with minimal halation, even from highly reflective samples.

3. Coded hardware saves observation settings for faster inspections and improved productivity

When used with OLYMPUS Stream software, the GX53 microscope can save observation settings, such as the observation technique, brightness, and objective lens type. This helps improve user productivity and facilitates inspections by making it easy to replicate frequently used observation settings or settings provided by other users.

GX53 Main Specifications

| Observation method | Reflected: Brightfield, darkfield, simple polarized, differential interference contrast, and MIX Transmitted: Brightfield, simple polarized |

| Optics | UIS2 optics |

| Reflected/Transmitted | LED light source |

| Stage | Maximum stroke 50 × 50 mm |

| Weight | 25 kg approx (microscope only: 20 kg) |

Overview of OLYMPUS Stream v. 2.3 Update

OLYMPUS Stream image analysis software v. 2.3 supports every step of the inspection process, from preparing the microscope for use through observation, analysis, and reporting. The latest update includes an instant extended focus image (EFI) function to bring the entire view field into focus. The software also incorporates improvements to the system’s spreadsheet-based reporting functions.

For more information

Press releases are company announcements that are directed at the news media.

Information posted on this site is current and accurate only at the time of their original publication date, and may now be outdated or inaccurate.